Generally regarded as low‑hazard polyols. Hygroscopic—keep closed

to avoid moisture uptake. Spills are extremely slippery. Avoid

overheating (> 200 °C) to limit degradation. For pharmaceutical

uses, specify compendial grade (USP/Ph.Eur.).

Average MW (Mn)

200 → 8000

Hydroxyl value

≈ 560 → < 15 mg KOH/g

Water (Karl Fischer)

≤ 0.5%

Color (APHA)

≤ 50

pH (5% aq.)

5.0–7.5

Representative ranges; exact targets depend on molecular weight

and grade. Shipped material conforms to COA for the lot.

| Parameter | PEG 200 | PEG 400 | PEG 600 |

|---|---|---|---|

| Appearance @ 25 °C | Clear liquid | Clear liquid | Clear viscous liquid |

| Viscosity (25 °C) | ~ 45–70 mPa·s | ~ 80–110 mPa·s | ~ 110–150 mPa·s |

| Hydroxyl value (mg KOH/g) | ~ 560–580 | ~ 260–290 | ~ 180–210 |

| Water | ≤ 0.5% | ≤ 0.5% | ≤ 0.5% |

| Acid value | ≤ 0.1 mg KOH/g | ≤ 0.1 mg KOH/g | ≤ 0.1 mg KOH/g |

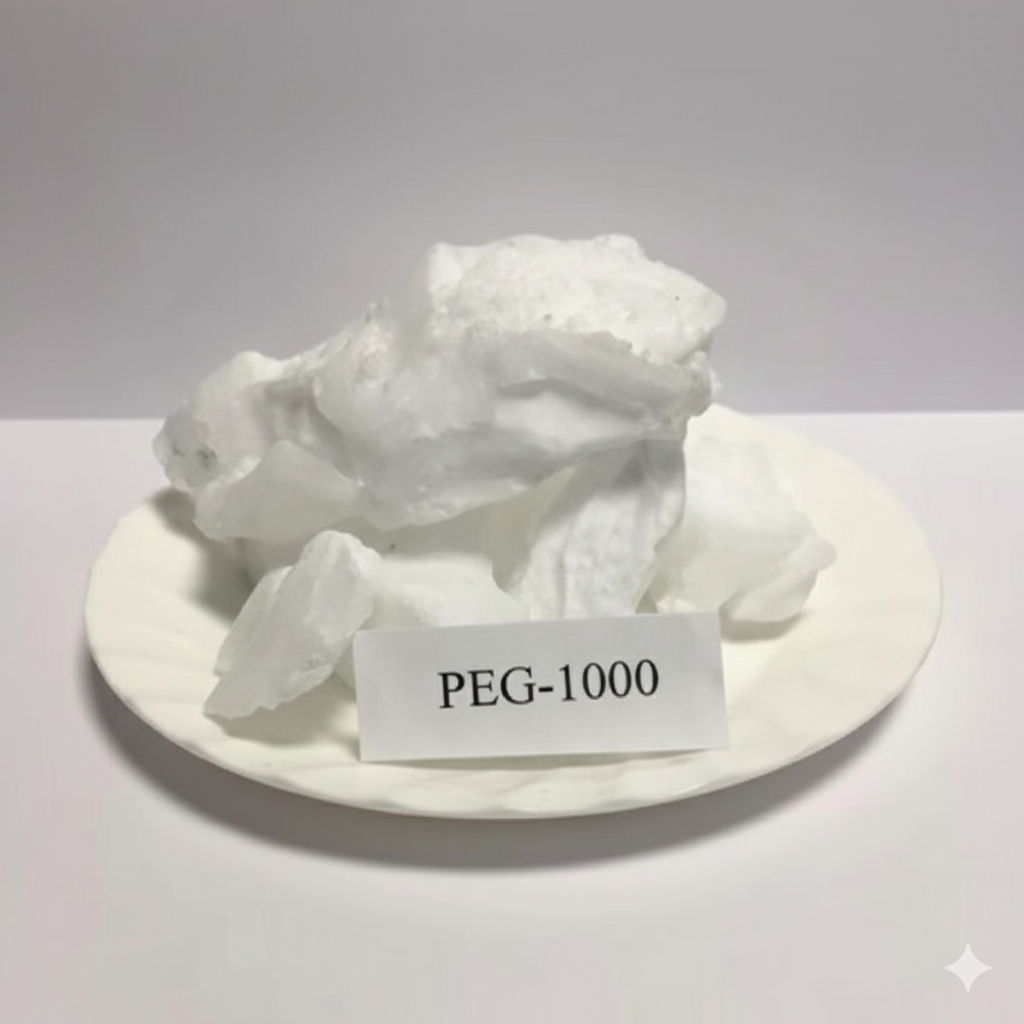

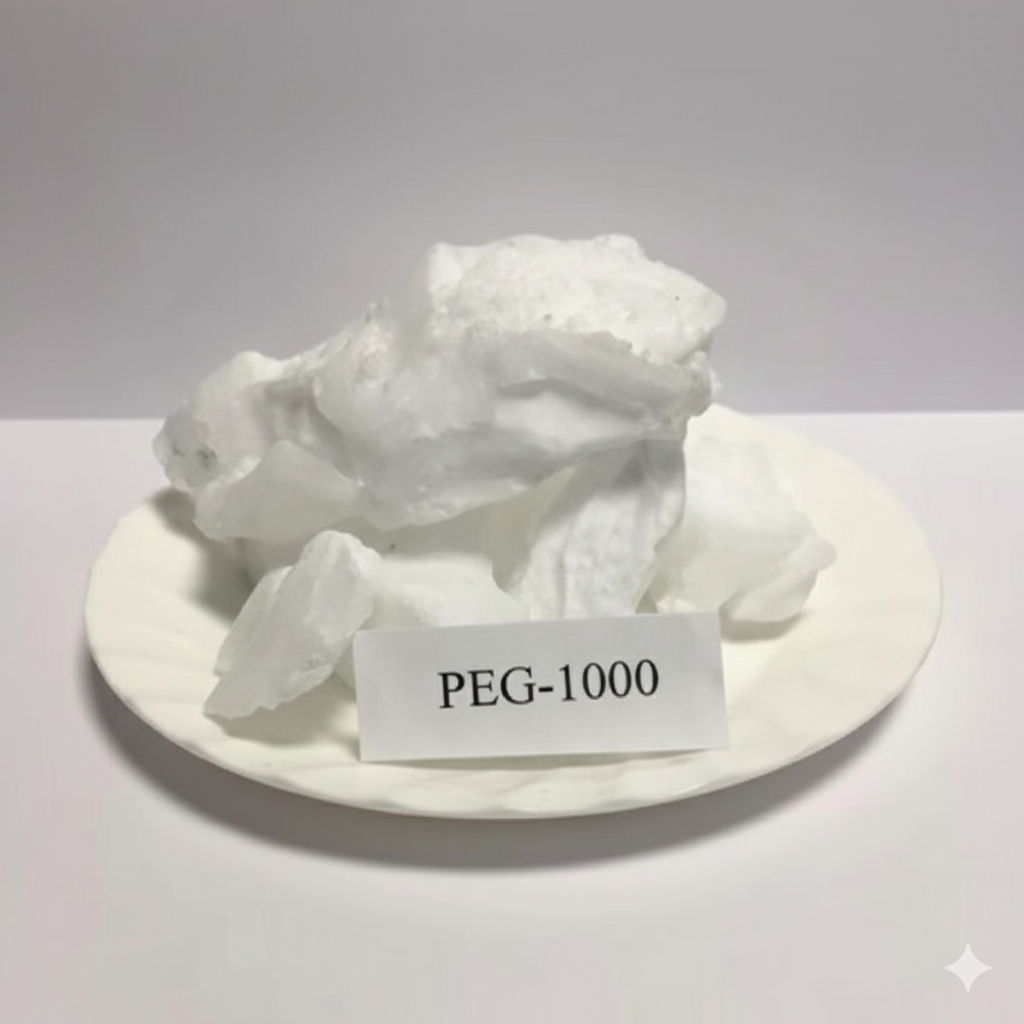

| Parameter | PEG 1000 | PEG 1500 |

|---|---|---|

| Appearance @ 25 °C | Soft waxy solid | Soft waxy solid |

| Melting range | ~ 37–42 °C | ~ 44–48 °C |

| Viscosity (60 °C) | ~ 50–90 mPa·s | ~ 100–150 mPa·s |

| Water | ≤ 0.5% | ≤ 0.5% |

| Color (APHA) | ≤ 50 | ≤ 50 |

| Parameter | PEG 4000 | PEG 6000 | PEG 8000 |

|---|---|---|---|

| Appearance @ 25 °C | White flakes/pastilles | White flakes/pastilles | White flakes/pastilles |

| Melting range | ~ 53–58 °C | ~ 58–64 °C | ~ 60–65 °C |

| Viscosity (100 °C) | ~ 150–250 mPa·s | ~ 250–400 mPa·s | ~ 300–500 mPa·s |

| Water | ≤ 0.5% | ≤ 0.5% | ≤ 0.5% |

| Color (APHA) | ≤ 50 | ≤ 50 | ≤ 50 |

| Parameter | Typical | Spec (USP/Ph.Eur.) |

|---|---|---|

| Compliance | USP/Ph.Eur. monographs | As ordered |

| Ethylene oxide/1,4‑dioxane | Compliant (trace limits) | Per pharmacopeia |

| Heavy metals (as Pb) | Meets monograph | Per pharmacopeia |

| Microbiological | Meets monograph | Per pharmacopeia |

| Additives | BHT‑free or with antioxidant | As ordered |

| Applications | Packaging | Storage & Handling |

|---|---|---|

|

• Humectant/solvent in personal care and HI&I.

• Plasticizer, lubricant and release agent in plastics/rubber. • Pharma excipient (ointments/bases), tablet lube/binder (compendial grades). • Carrier in agro and inks; heat‑transfer fluids (low‑toxicity blends). |

• Liquids (PEG 200–600): 200–230 kg drums • 1000–1250 kg

IBCs • bulk.

• Solids (PEG ≥1000): 25 kg bags • 500–1000 kg big bags. |

• Keep closed, dry and clean; avoid moisture pickup.

• Stainless steel recommended; avoid reactive soft metals at high temp. • Mix before use if partially solidified; heat gently (≤ 70 °C) to melt solids. |

Values above are indicative; specify **molecular weight**, **grade

(industrial or pharma)**, and any **additive preferences

(BHT‑free)** when requesting a quote.