Customer

Regional confectionery brand shifting to phthalate-free while keeping mouthfeel, flavor and line speeds identical.

Challenge

- Match chew/elasticity and gloss on current SKUs.

- Hit local migration targets and maintain “phthalate-free” labeling.

- No flavor pickup, no haze, no cycle-time penalties.

Approach

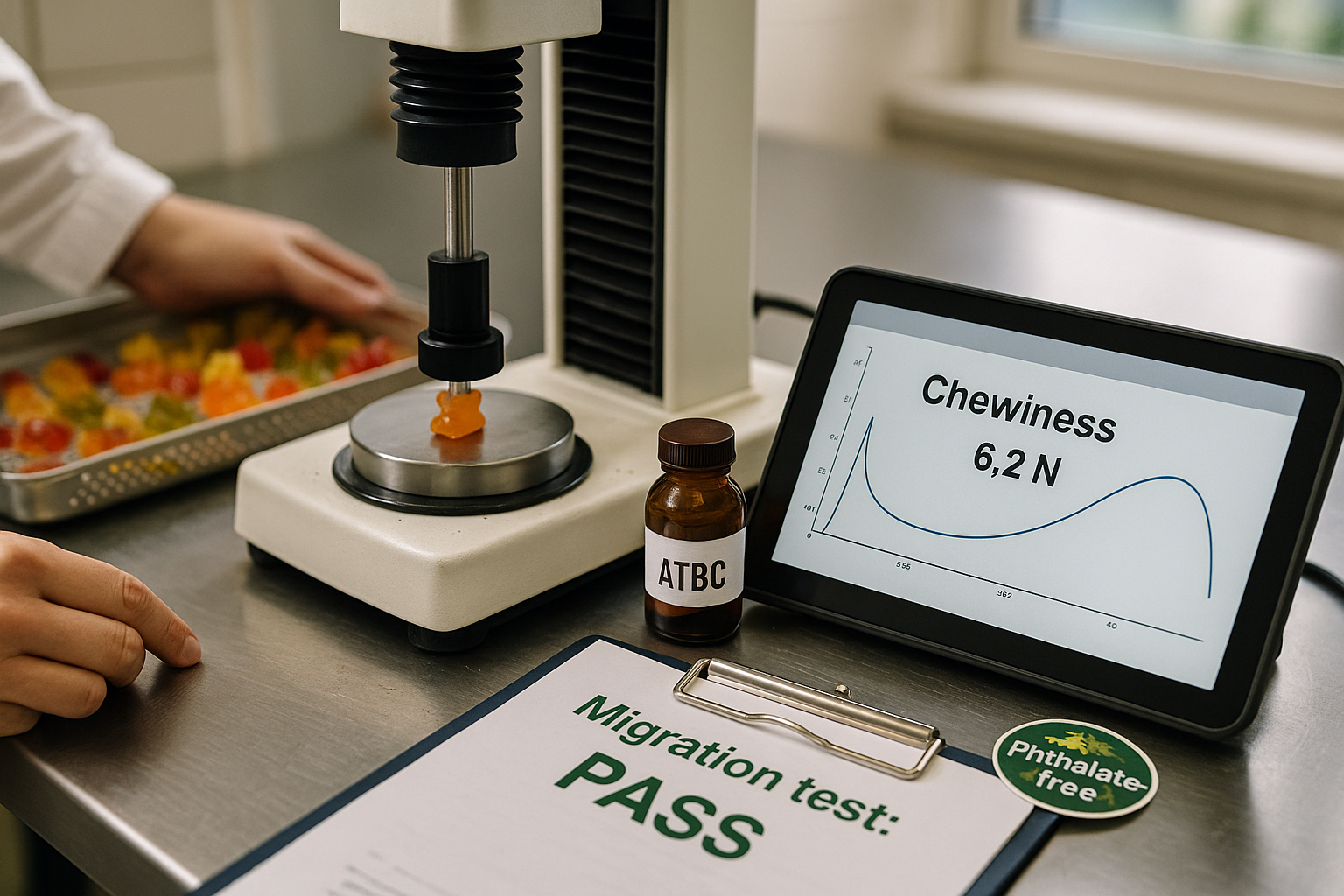

Screened citrate esters; ATBC provided the best texture retention at low treat rates with minimal sensory impact. Dosed post-cook to reduce volatilization and retained dispersion with a brief high-shear mix.

Formulation window

| Component | Function | Use level | Notes |

|---|---|---|---|

| ATBC | Plasticizer | 0.3–0.8% w/w | Tune vs. gelatin/pectin ratio and target chew. |

| Gelatin / Pectin | Gelling | Per SKU | Bloom/DE as per house spec. |

| Citric / Malic acid | pH & taste | 0.3–0.7% | Balance set and sourness. |

| Antistick glaze | Handling | qs | Vegetable oil/wax as needed. |

Processing & validation

-

Cook & hydrate

Cook syrup to target °Bx; hydrate gelatin/pectin per spec. Add acids post-cook.

-

ATBC addition

Add post-cook < 80 °C with brief high-shear mix for uniform dispersion.

-

Deposit & dry

Deposit at 70–75 °C; control RH 45–55%. Dry to target aw.

-

Testing

TPA texture vs. control; sensory triangle; turbidity; overall/specific migration per local regs.

Results

Chew and elasticity matched within ±5%; no flavor pickup; clarity on-spec; line speed unchanged.

Panel confirmed identical chew; packaging stability unchanged.