Customer

Regional blender supplying gear oils for mobile and industrial drives; complaints on viscosity drop after service and shear-down in field.

Challenge

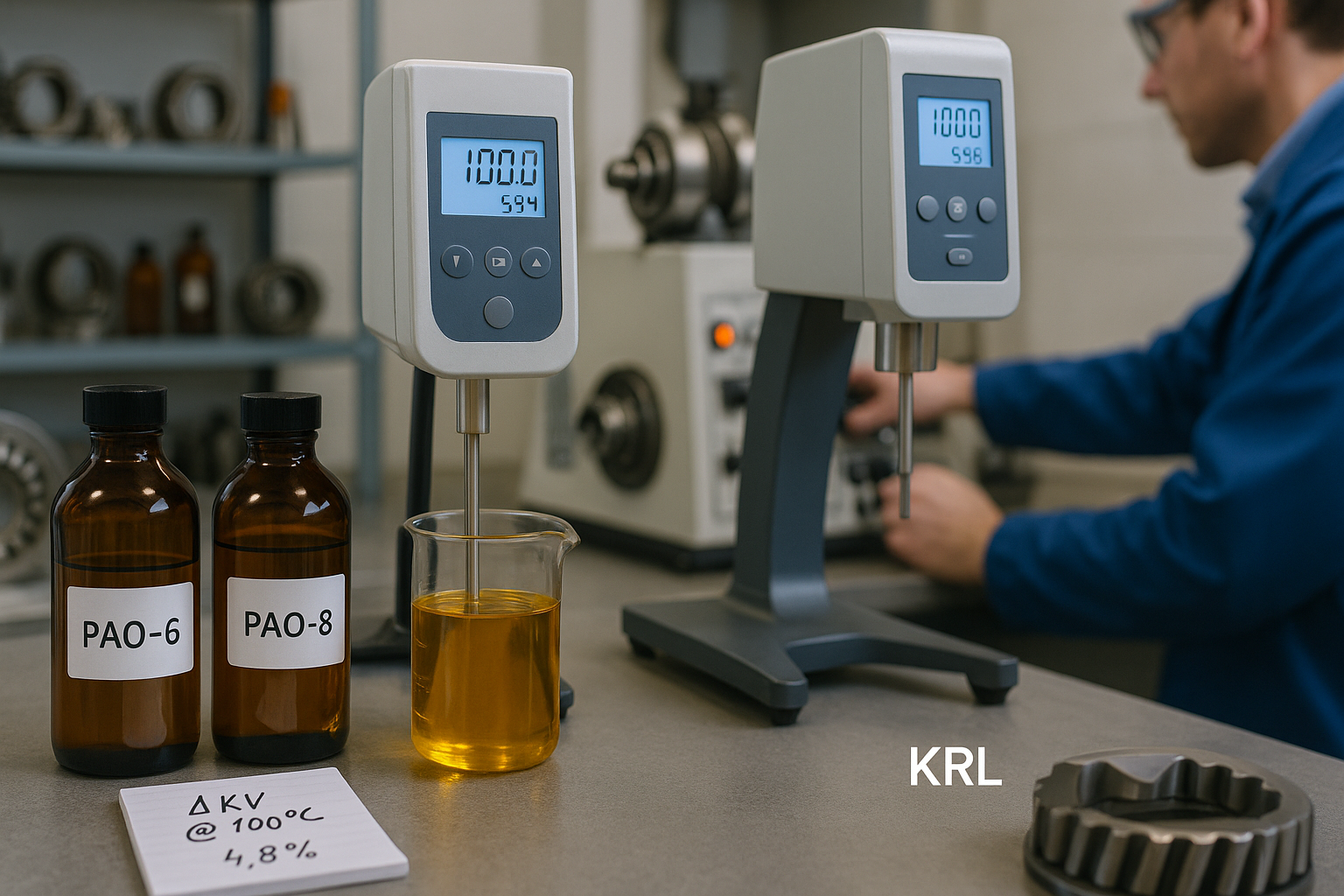

- Shear loss in KRL > 15% with incumbent OCP VI improver.

- Cold-crank limits near spec; foam in Seq II.

- Hold cost and keep existing additive house where possible.

Approach

Blend design around PAO-6/8 with 10–15% synthetic ester for seal/solvency, a shear-stable OCP VI improver, and balanced ZDDP + S-P EP/AW. Anti-foam trimmed to hit Seq II.

Formulation window

| Component | Function | Use level | Notes |

|---|---|---|---|

| PAO-6 / PAO-8 | Primary base oil | 70–82% | Target ISO VG via ratio. |

| Synthetic ester | Polarity/low-temp | 8–15% | TMP/POE improves VI & seals. |

| OCP VI improver (shear-stable) | Viscosity index | 5–9% | Pre-dissolve @ 110 °C. |

| ZDDP | Antiwear | 0.6–0.9% | P content per spec. |

| S-P EP package | Load/scuff | 1.5–3.0% | Match GL-4/GL-5 target. |

| Antioxidant (phenolic/amine) | Oxidation | 0.3–0.6% | Thermal stability. |

| Antifoam (silicone) | Foam control | 5–15 ppm | Tune for Seq II. |

Processing & testing

- Charge base; dissolve VI improver at 100–115 °C, recirculate ≥ 30 min.

- Cool < 60 °C; add EP/AW, AO, antifoam; polish filter.

- Test: KRL 20 h, FZG A/8.3/90, D892 foam, D130 copper, D445 viscosity, Brookfield @ −40 °C.

Results

Viscosity loss 6–8% (KRL), FZG stage 12–13, Brookfield −40 °C 90–110k cP, Seq II foam 0/0. Field trials showed stable viscosity after 1,000 h and clean gear surfaces.